Business

Air Pollution Control Systems & Technical Services for Clean Air and Environment

Electrostatic Precipitator

Electrostatic Precipitator (EP/ ESP)PR Video

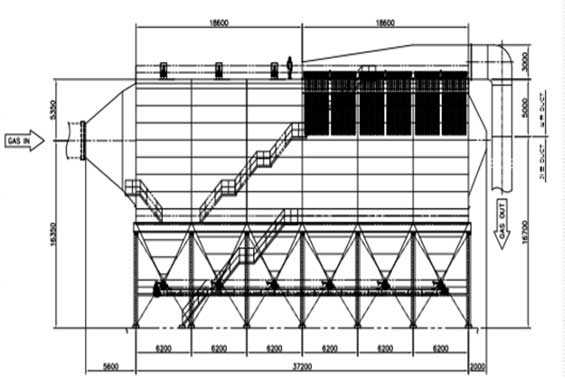

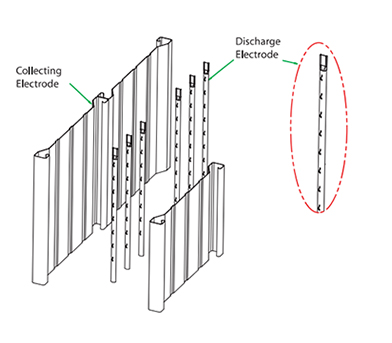

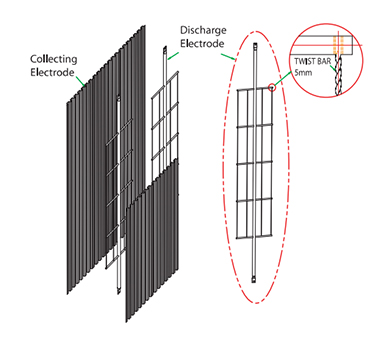

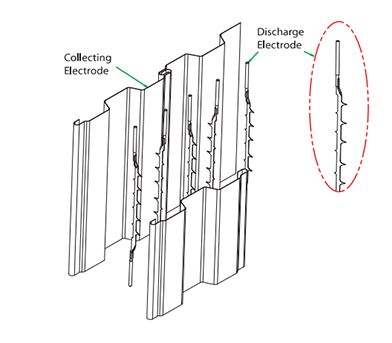

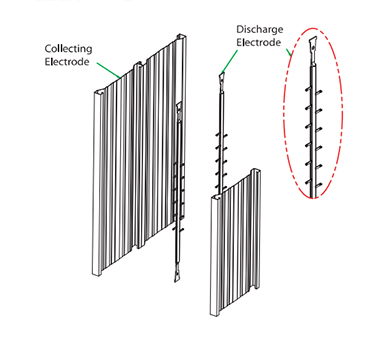

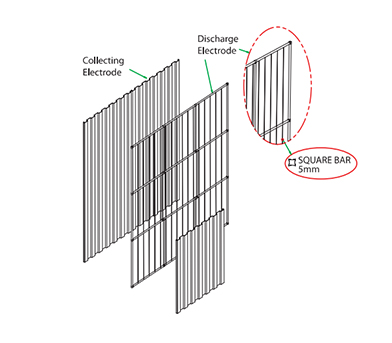

The EP is composed of DE, CE, Rectifier-TR & the control system, and rapping system. High voltage DC power rectified through TR is applied to the DEs to form an electric field and to generate corona discharge. EP stands for Electrostatic Precipitator. DE and CE stand for Discharge Electrode and Collecting Electrode (or Collecting Plate), respectively. When passing between DE and CE, the dust in the flue gas is charged by the negative ion, and attracted and collected to the positive pole of CE. The rapping system periodically removes the dust on the CE to hoppers. EPiT offers customized solutions and designs to customers based on the accumulated technology and track record in various industries.

Special features of EPiT Electrostatic Precipitator

- Economical and robust design

- High efficiency and energy saving design

- Customized optimal design for site condition

- Easy maintenance

KCC Yeoju Plant

Plate glass #1 electric dust

collector construction

SK Incheon Oil Refinery

EP401-1 FIELD extension construction

Hanjoo 250Ton Boiler EP

EPiT suggest a solution from an optimized and economical point of view through review of design data and site investigation.

1. Conversion of EP into Hybrid filter (EP + Bag Filter applying EPiT Pleated Bags)

The disadvantage of EP is that dust in the last field is scattered and discharged to the stack when rapping at last field. Accordingly, it is difficult to meet the recently strengthened emission regulations, and bag filters are installed instead of EPs. And in the case of the existing EP, it has been proposed and renovated as a hybrid filter (EP+Bag Filter). In this case, the area of the existing EP is normally limited, so it is difficult to apply normal round bags. EPiT solved this problem by applying its own model EPiT Pleated Bags, which is 2~3 times area of normal round bag.

- (1) By removing more than 80~90% of dust in the EP of the upstream part, the efficiency is improved and the bag life is extended in the bag filter at the rear.

- (2) The bag filter collects fine particles that are not collected by the EP.

- (3) By applying EPiT Pleated Bags, it is possible to make compact design with low ACR and short length bag. It improves dust collection efficiency and makes maintenance easier.

- (4) Even if a failure occurs in the EP, bag filter can control dust emission.

- * ACR (Air to Cloth Ratio): Amount of gas passing per unit area of filter bag in bag filter

Upgrade works of EP

Due to the economic recession and the strengthening of environmental regulation, most of companies want to improve performance through EP upgrade works rather than new installation or expansion. Accordingly, EPiT provides customized solution after studying its design data and drawings and carrying out internal inspection, including not only troubleshooting but also adjusting gas flow balance and supplementing EP internal configuration.

- Much more economical than extension work

- It takes short time than extension work

- Less area for installation

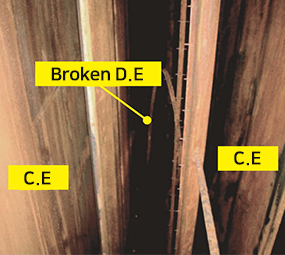

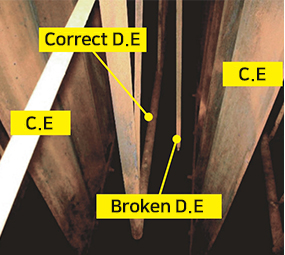

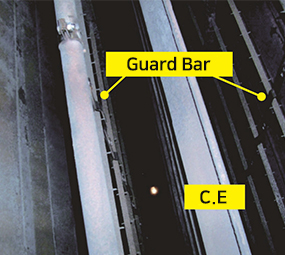

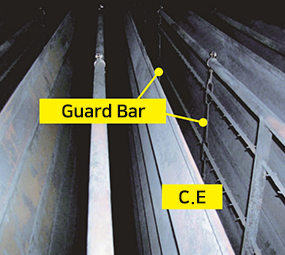

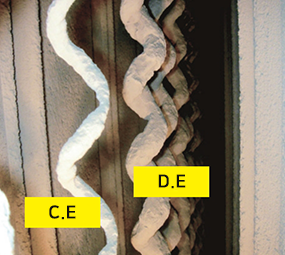

1. Guard bar for Discharge Electrode

A discharge electrode could be damaged or partly broke after long operation. The broken discharge electrode will be closer or contact to collecting plate or EP casing and cause electrical short. In the end, EP will be stopped. It brings about huge production loss and cost.

Even if a discharge electrode is broken, discharge electrode guard prevents the damaged electrode from contacting collecting plate or EP shell. So, EP can work continuously without stopping.

-

- Broken D.E (1)

-

- Broken D.E (2)

-

- Guard Bar (1)

-

- Guard Bar (2)

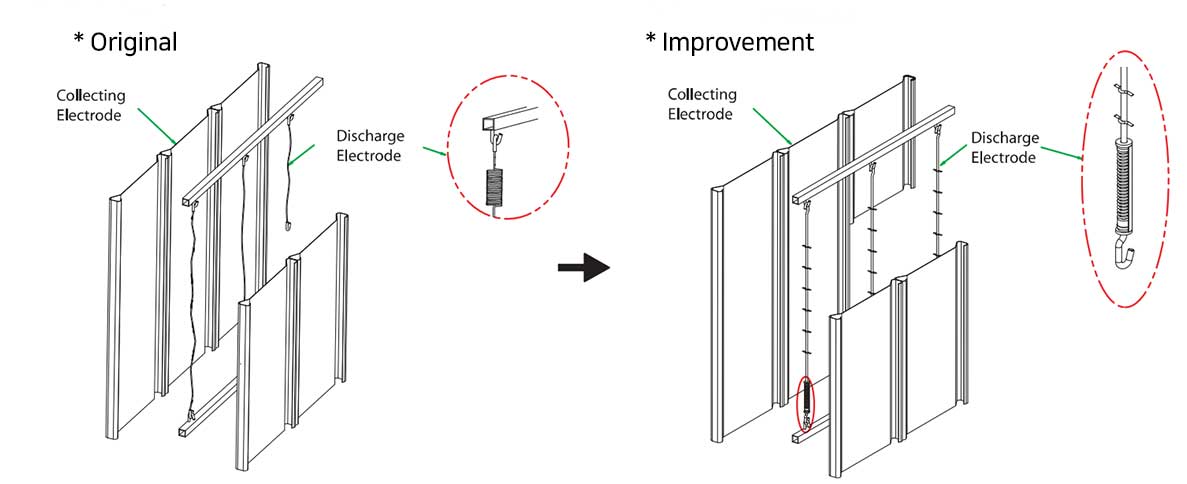

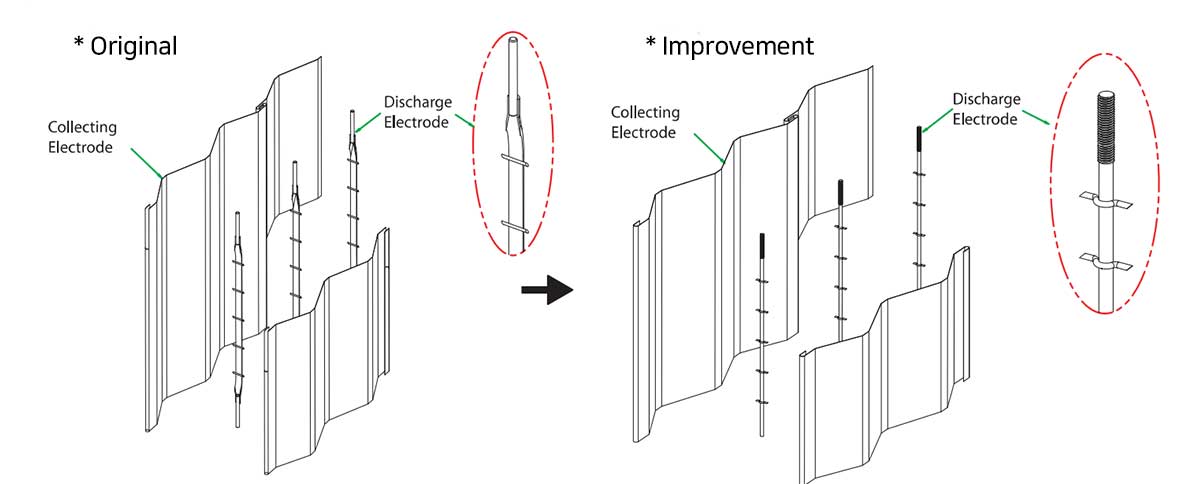

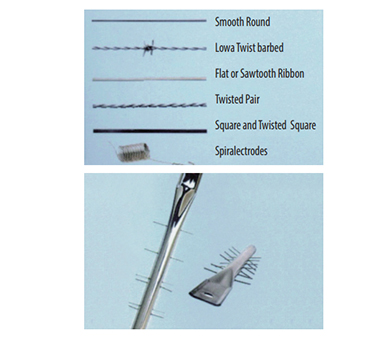

2. Improvement of discharge electrode

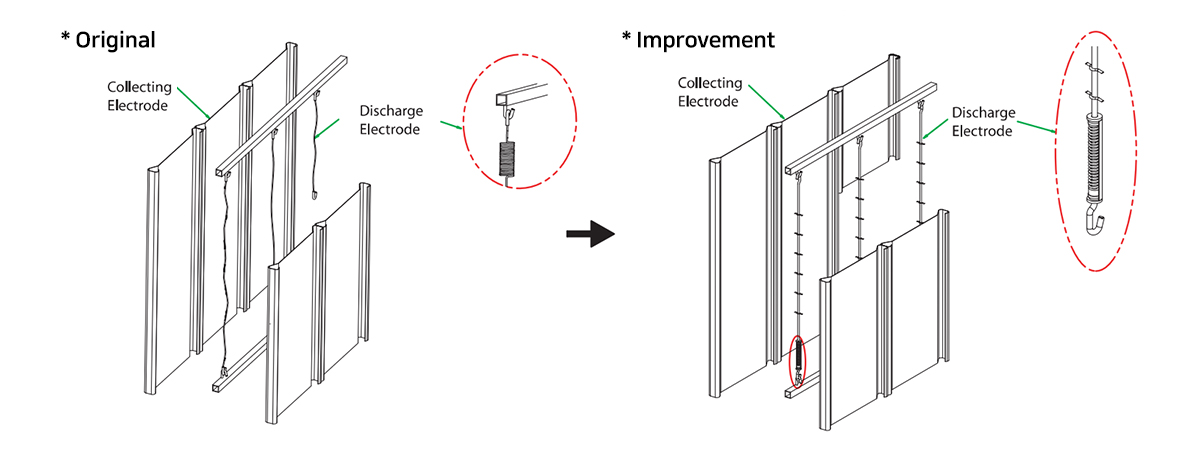

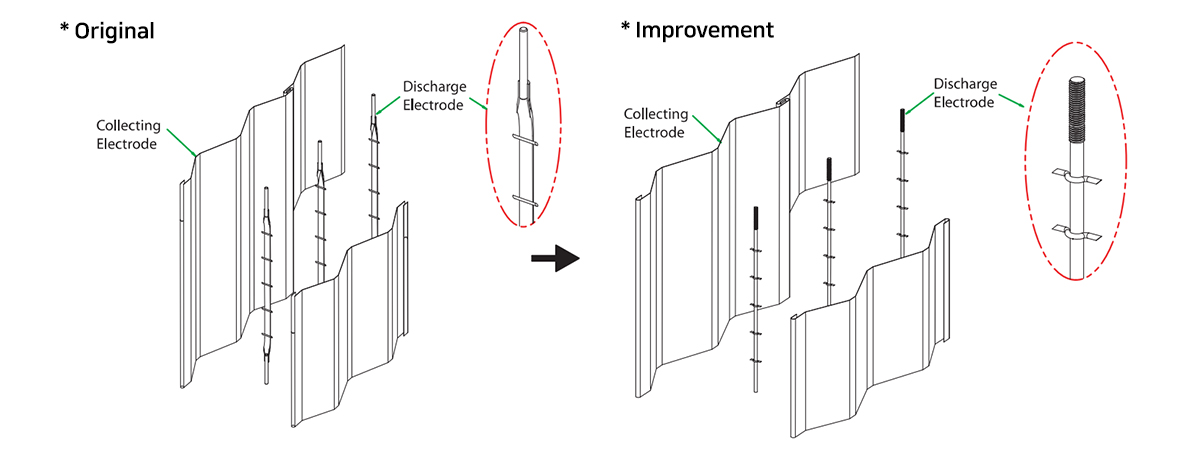

Some electrodes have caused troubles during installation and/or operation. EPiT is providing improved DEs.

1) DE of spring type connection easily leaves and falls down from its position by electrical vibration. Finally, it causes electric short. So, we improved its connection type.

2) EPiT improved the neck of discharge electrode and increased its lifetime, which is vulnerable to wear down. In addition, it improved DE hanging hook from welding type to screw type easy to install and able to adjust DE tension. It prevents DE from swing so as to stabilize electric fields and EP efficiency.

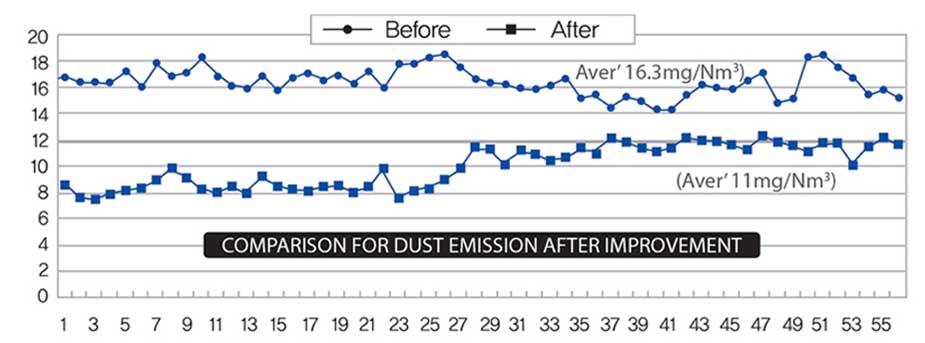

3. Upgrade case of SSangyoung Cement Co., Ltd.

Dust was emitted slightly exceeding permissible level of 12mg/Nm3 from the #4 Kiln cooler EP in Yongwol plant. So, it asked EPiT to improve EP below this emission level with cost effective way. EPiT successfully completed the upgrade works without any extension of EP, on April 2011. After deeply studying its design data and investigating internal configuration, EPiT improved gas flow to prevent re-entrainment by adjusting perforated plates, vanes and etc. Consequently, 32% of dust emission had been improved, being under 12mg/Nm3. (Refer to below table) This upgrade work has the same effect as extending the EP by 7%.

· Design Data

| Gas volume (Q) | Nm3 | 3300 |

| Gas temperature | ˚C | 240 |

| Inlet dust loading (Ci) | g/Nm3 | 10 |

| Outlet dust loading (Co) | g/Nm3 | 0.05 |

| Efficiency | % | 99.5 |

· Comparison tabe before / after upgrade work

| Unit | Before | After | Result | |

|---|---|---|---|---|

| Outlet dust load | mg/Nm3 | 16.3 ~ 20 | 12 | 27 ~ 40% improvement |

| Collecting area | % | 10 | Same effect of 7% ESP extension |

· Comparison of dust concentration before / after upgrade work

EPiT provides operating and maintenance consulting services to ensure EP system are in excellent condition before or when they cause problems.

1. Trouble shooting

| No | Trouble | Cause | Measure |

|---|---|---|---|

| 1 | Periodically hunted current | Swing of electrodes | Internal EP check |

| Trouble of controller | Replacing controller | ||

| 2 | High voltage and current spark | Maintaining high discharge volt | Reset voltage lower |

| 3 | Often hunted current (especially 1st field) |

Checking when it happen at rapping. (It happens temporarily when sticked dusts are removed from electrodes) |

Regulating rapping cycle |

| 4 | Periodical dusts outlet at stack |

Dust re-entrainment | |

| Uneven gas flow | Check EP gas flow | ||

| At rapping | Regulating rapping time | ||

| 5 | Getting volt and current lower when long operation | Dust deposit on collectiing and discharge electrodes | Checking rapping system and gas temperature |

| 6 | When T/R panel is switched on, its lamps are on but all meters indicate '0'. | 2 SCR's were wire down or damaged. | After checking SCR gate line, replacing SCR or not. |

| Connecting defect of SCR gate line | |||

| Polarity of SCR gate line were changed | After checking SCR line, re-connect it | ||

| 7 | Spark and arc continue occrurring when 2nd voltage and current are '0'. | Discharge electrode is nearly ground condition or grounded. | Check high tension line Check dust in hoppers Check space between collecting and discharge electrodes |

| 8 | 1st voltage gets high while 1st & 2nd current and 2nd voltage is '0' | T/R is separated from T/R panel | Check its connection |

| 1st coil of T/R is open | Check T/R | ||

| 9 | 1st and 2nd voltage get higher, while 1st and 2nd current keep '0' | High tension line is separated between T/R and EP | Check high tension line |

| 2nd coil of T/R is open | Check T/R insulation and resistivity of rectifier (If it is normal, correct opened 2nd coil of T/R.) | ||

| 10 | 1&2nd voltage, and 1&2nd current are getting higher at panel 'on', after then trip. | Defect on SCR (Short) | Replace SCR |

| 11 | Spark and arc continued at '0' of 2nd voltage and current, and then it tripped as 'under voltage'. | After separating T/R high tension lin e and regulating 2nd voltage limit as 10 kV, only 1&2nd voltage are getting higher when T/R is 'on' | Check EP inside |

| After separating T/R high tension lin e and regulating 2nd voltage limit as 10 kV, spark and arc continue at 2nd voltage of 0 kV when T/R is 'on' | Please contact us | ||

| 12 | NFB is 'on', but 'off' lamp does not light 'on' | Lamp is burnt | Replace lamp |

| Power is not supplied | Check main supply Check main fuse Check control power |

||

| NFB does not contact well | Check NFB | ||

| 13 | Start button is 'on', 2nd current is not indicated.(1st current is indicated) | 2nd current meter does not work | Replace meter |

| Protection module does not work | Replace module | ||

| Control does not work | Replace controller |

2. Maintenance work

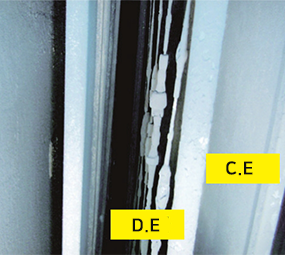

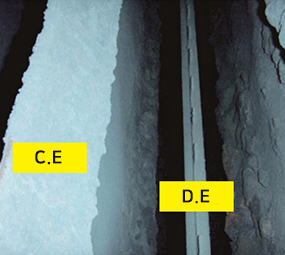

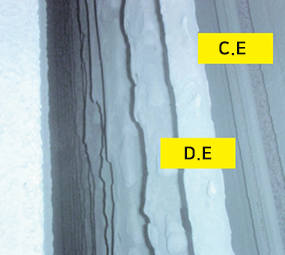

Cleaning (Collecting Electrodes/Discharge Electrodes)

Dust can stick to DEs and/or CEs due to rapping system failure. This dust forms abnormal protrusions and interferes with stable corona discharge, and causes arc and back corona. It makes difficult to maintained good condition of discharge voltage and current. Finally, the collection efficiency is significantly lowered.. Even if the rapping system is corrected, it is difficult to remove the stuck dust by rapping. The stuck dust must be removed by using cleaning method suitable for the dust properties.

-

- HHIC TYPE

-

- KC TYPE E.P

-

- GADELIUS TYPE E.P

-

- FLS TYPE E.P

※ Dusts sticked on CE & DE

Collecting Plates and Discharge Electrodes

-

- Bent Collecting Plates

-

- After Correction

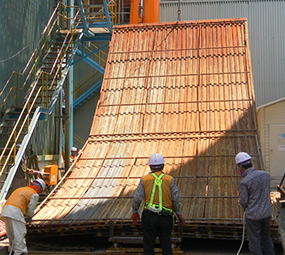

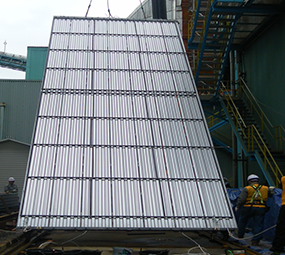

Replacement project of Collecting Plates

-

- Before replacement of CE

-

- After replacement of CE

-

- Replacement of CE 1

-

- Replacement of CE 2

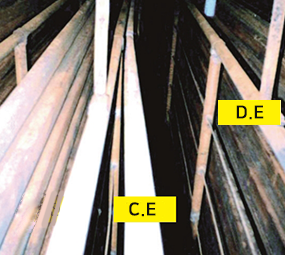

Replacement project of Discharge Electrodes

-

- Assembling DE

-

- Assembled DE

-

- Replacement of DE

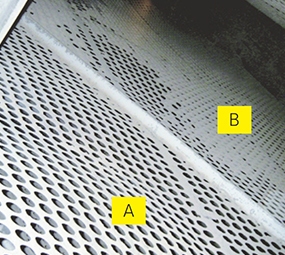

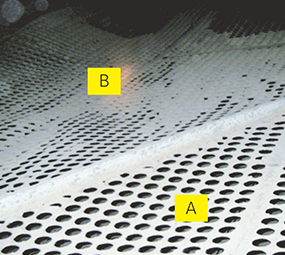

Gas Flow Balance

Gas flow balance has a significant effect on dust collection efficiency. When the dust collection efficiency is not good despite the voltage and current reaching the design values, or when the dust collection efficiency gradually decreases during long-term use, the gas flow distribution is often poor.

-

- Comparison of Gas Flow Balance

-

- Comparison of Gas Flow Balance

-

- Comparison of Gas Flow Balance

-

- Comparison of Gas Flow Balance

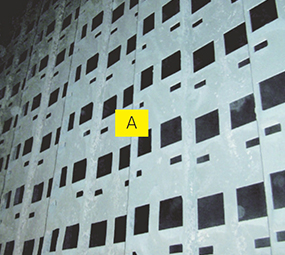

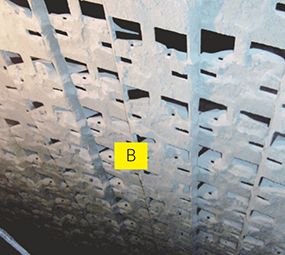

During initial operation, the perforated plate is clean as “A”. If flow balance is poor, dust will stick to the perforated plate like “B” and the gas flow becomes worse. And the dust collection efficiency decreases.

-

- Comparison of Gas Flow Balance

EPiT manufactures and supplies electrostatic precipitator parts on our own production line.

Namdong factory

Manufacturing Collecting plates

Namdong factory

Manufacturing Collecting plates

Namdong factory

Manufacturing Discharge electrode

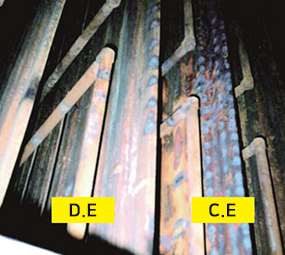

1. Collecting Plates(CE) and Discharge Electrodes (DE)

EPiT has the molds and roll forming line for the following types of CEs & DEs.

(* Gadelius, Lurgi, FLS miljo, Toyo, MHI, ELEX, and HHIC type )

-

- GADELIUS TYPE

-

- LURGI TYPE

-

- FLS MILJO TYPE

-

- FLS MILJO TYPE

-

- FLS MILJO TYPE

-

- FLS MILJO TYPE

-

- FLS MILJO TYPE

-

- FLS MILJO TYPE

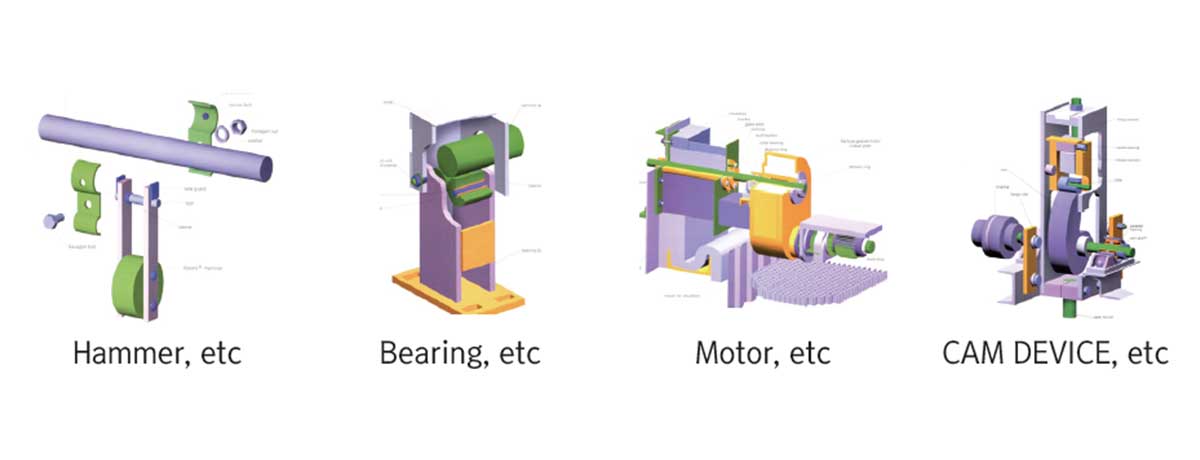

2. Rapping system

-

- Rapping system

3. Control Equipments & Insulators, etc

-

- Control equipments

-

- Insulators