Business

Air Pollution Control Systems & Technical Services for Clean Air and Environment

Bag Filter

Bag FilterPR Video

The bag filter is installed at the rear end of industrial plant and serves to filter dust from flue gas. The clean air is discharged to the stack through filter bags and connecting duct, and the dust collected on the surface of filter bags will be removed by pulse jet air after reaching to some differential pressure to the hopper. Gases containing not only various types of dust, but also high concentrations of dust can be efficiently treated. The filter bag material is selected in consideration of the gas/dust characteristics and temperature, and etc.

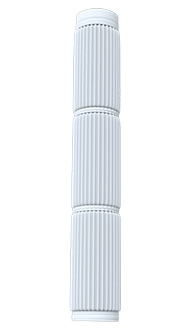

What is EPiT Pleated Bag?

EPiT developed the “EPiT Pleated Bag” through continuous research and development, registered patents in 2013. Since then, EPiT has been manufacturing and supplying EPiT pleated bags. As shown below, EPiT pleated bag is possible to make the compact engineering/design and excellent performance and energy saving has been proven, making a good solution for customers.

1. Shape of EPiT Pleated Bag

-

- EPiT Pleated Bag

-

Excellent R&D

Excellent R&D

Innovative Product

-

- Bag filter for testing

-

Installation of

Installation of

EPiT Pleated Bags in the test B/F

2. Advantages of EPiT Pleated Bag

-

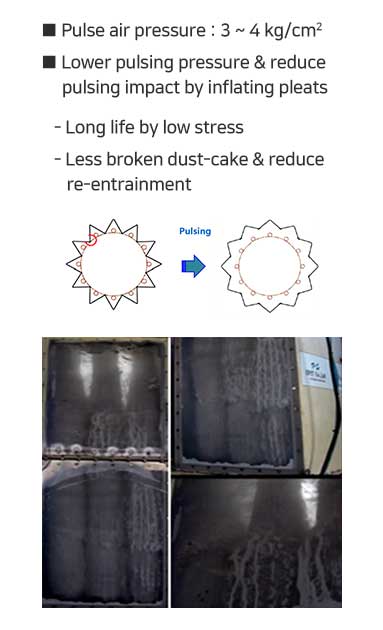

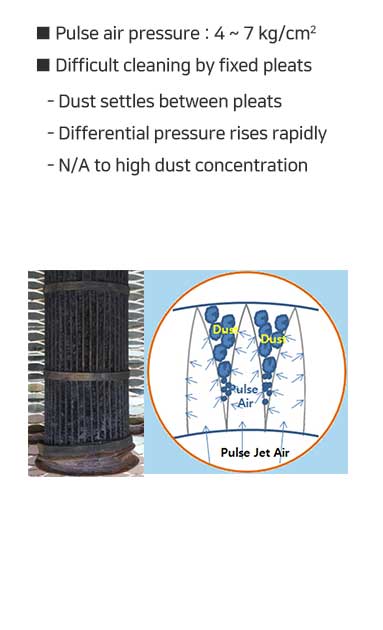

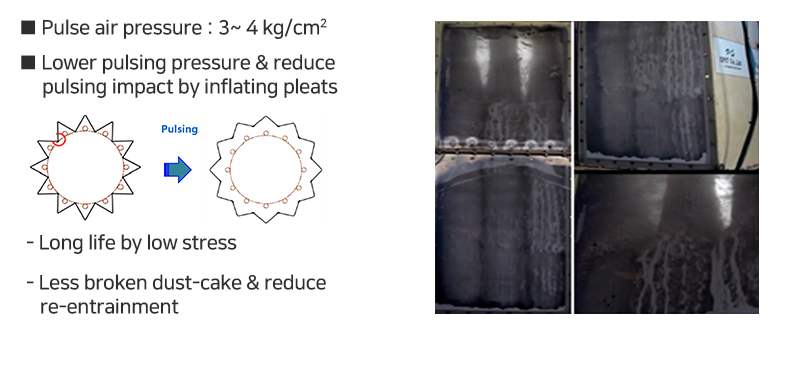

1) EPiT Pleated Bag has non-fixed flexible pleats.

When pulsing, the pleats are spread out, and after pulsing it returns to its original state.

(* Cartridge pleated bags are a completely different type of pleated bags, having fixed pleats in a frame.))

- 2) 200~300% filtration area compared to the existing round bags (refer to 『Comparison of pulsing mechanism』 below)

- 3) Lower pressure pulsing than that of existing round bag

It increases dust collection efficiency by minimizing dust scattering and re-entrainment

It reduces impact on the base fabric of the pleated bags and reduces stress, making a longer life (about 1.5 to 3 times that of a round bag)

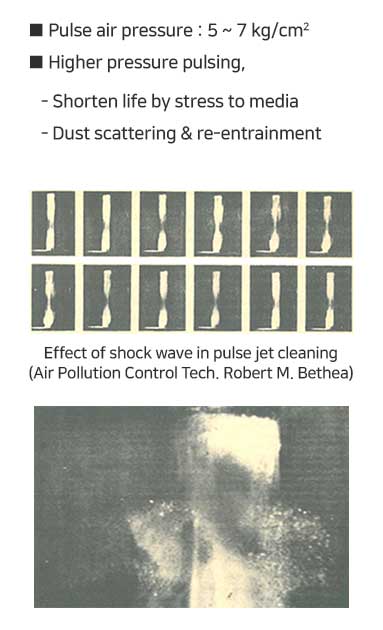

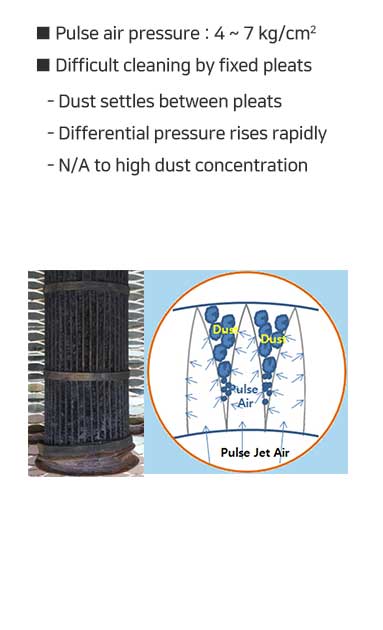

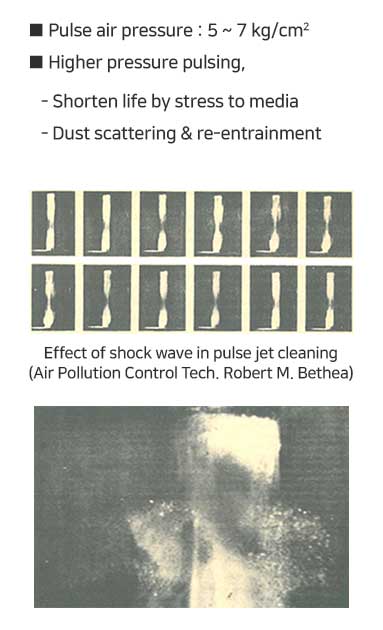

<Comparison of pulsing mechanisms>

The pulsing mechanisms are compared for the three types of bags that are widely used as below table.

It shows that the pulsing mechanism has a great influence on the operation efficiency as well as the dust collection efficiency of the bag filter.

-

- EPiT Pleated Bag

-

- Round Bag

-

- Catridge Pleated Bag

-

- Round Bag

-

- Catridge Pleated Bag

-

- EPiT Pleated Bag

-

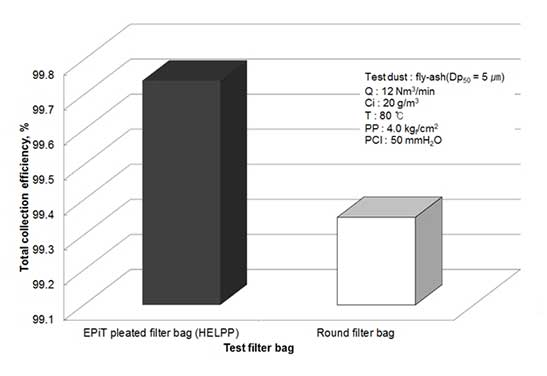

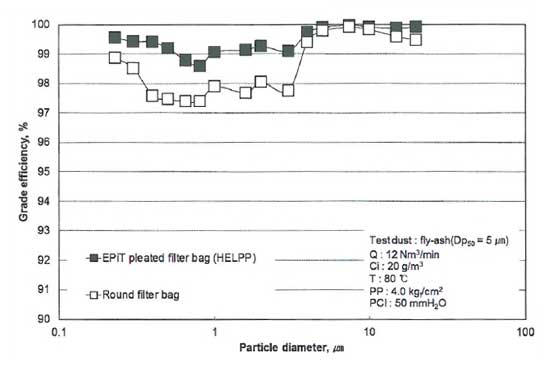

4) Excellent in dust collection efficiency (KIER Test Report)

High dust collection efficiency/ Excellent in part of dust collection efficiency fine dust/ultra-fine particles)

-

Total collection efficiency Round Bag 99.35% EPiT Pleated Bag 99.74%

-

Particle Diameter 0.3µm 1µm 2.5µm Round Bag 98.51 % 97.51 % 98.05 % EPiT Pleated Bag 99.43 % 99.06 % 99.27 %

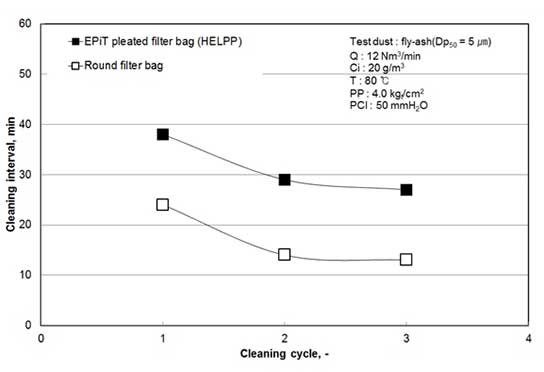

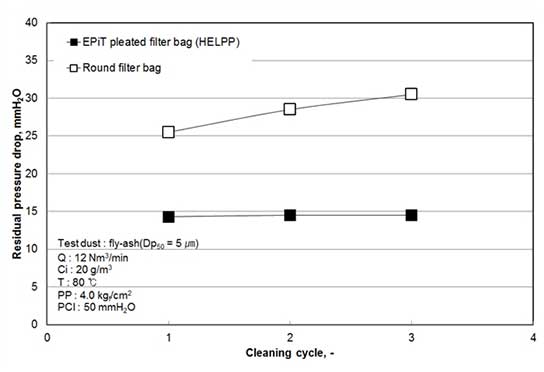

Comparison of pulsing interval and residual pressure loss

The EPiT Pleated Bag has less re-entrainment, so after pulsing, there is less residual pressure loss compared to the round bag. (It takes longer to reach the set ΔP by dust accumulation than that of a round bag).

-

Total collection efficiency Round Bag 99.35% EPiT Pleated Bag 99.74%

-

Particle Diameter 0.3µm 1µm 2.5µm Round Bag 98.51 % 97.51 % 98.05 % EPiT Pleated Bag 99.43 % 99.06 % 99.27 %

- If the above pulsing interval covert into the number of pulsing per year (300 days)

Round bag is equivalent to pulsing 12,000 times a year.

And, EPiT Pleated Bag is equivalent to pulsing 5,100 times a year.

(* The more times the filter is pulsed, the faster the filter wears and deteriorates. Because a strong impact by high pressure air is applied to the filter bag, when pulsing.)

- 5) Compatible with existing round bags

- - The capacity/performance can be improved without modification of existing facilities (tube sheet, etc.)

- - No need for additional verification of the fabric by using the same fabric with existing round bag.

3. EPiT has its own factory that produce EPiT Pleated Bag on the 4th floor of the headquarter.

- 1) Customized design and products

- 2) Immediately reflection and improvement of site problem

- 3) Continuous improvement/innovation through self-development

- 4) Securing competitiveness through productivity/quality improvement

4. Intellectual property rights and certificates for EPiT Pleated Bag

- 1) Patents

13 patents registered (including US, Japan, and Southeast Asia as well as domestic)

- 2) Certificates

Excellent R&D Innovative Product from Ministry of Environment, Korea & KEITI on June 30, 2020

Excellent Quality from Incheon Metropolitan City , August 21, 2020

-

- [Patent] Filter for bag filter

-

- Excellent R&D Innovative Product

-

- Excellent Quality from Incheon Metropolitan City

When installing a new bag filter, applying EPiT pleated bag has the following advantages.

| Advantage | Effects by EPiT Pleated Bags |

|---|---|

Compact design |

|

Increase dust collection efficiency |

|

Reduce operation cost |

|

Longer filter bag life expectancy |

|

Easy Maintenance |

|

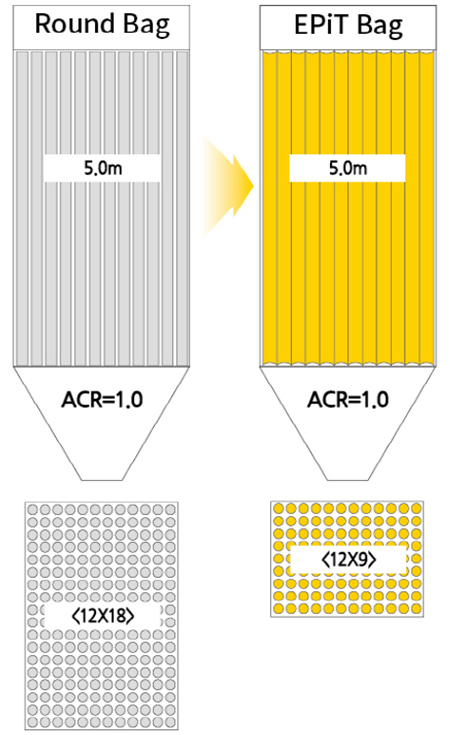

1) Advantages of newly installing a Bag Filter with EPiT Pleated Bag applied

(Design more compact Bag Filter design when EPiT Pleated Bag is applied)

- Decrease initial invest cost, internal parts and area by reducing Bag Filter size to 1/2

- Effective solution when the installation site is narrow or there is a height limitation

- Saving operation and maintenance cost

bag filter size comparison between round bags and EPiT Pleated Bags

When improving performance of the existing bag filter the problem of the existing B/F can be solved by applying the EPiT Pleated Bag.

| Improvement of Existing B/F | Effects by EPiT Pleated Bags |

|---|---|

Compatible with round bags |

|

Lower pressure drop |

|

Improve collection efficiency and reduce frequent bag replacement |

|

Improve cleaning efficiency |

|

Improve replacement of bags |

|

Improved economic efficiency |

|

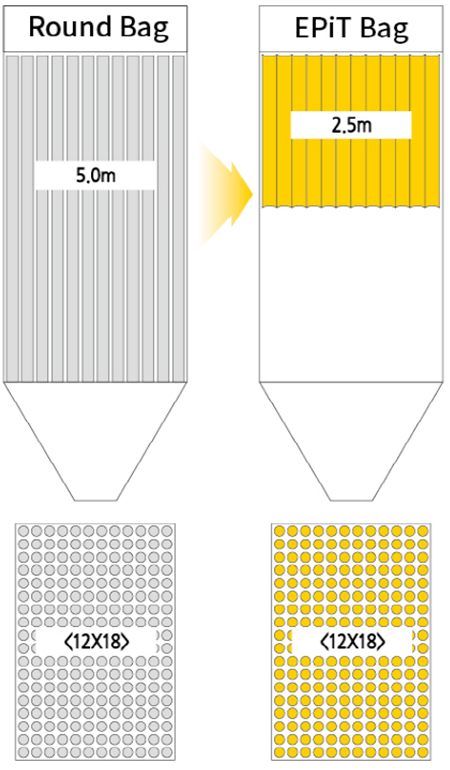

1) Improve existing Bag Filter with applying EPiT Pleated Bags

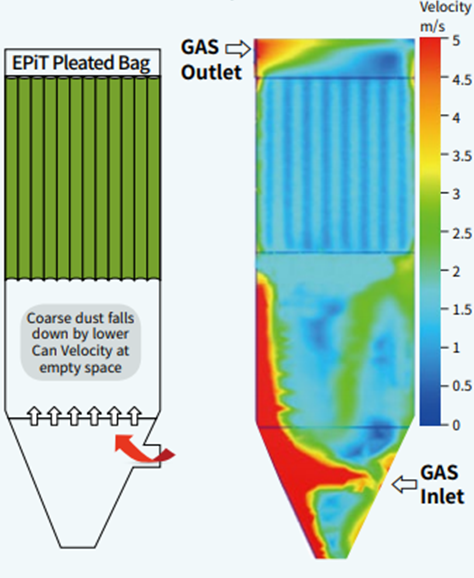

If the existing filter bag composed of 120ea 4m-long round bags in one compartment, it can be improved by reducing the length to 2m when applying EPiT Pleated bags. When we use the long round bag, the bag has some problems such as abrasion or damage due to bag-to- bag collision at the bottom, and un-cleaned bag bottom. Shorter bag length reduces damage and improves the performance of the filter bag (refer to CFD data below)

applying short EPiT Pleated Bags

2) Improvement effect when replacing the round bags with short length EPiT Pleated Bags

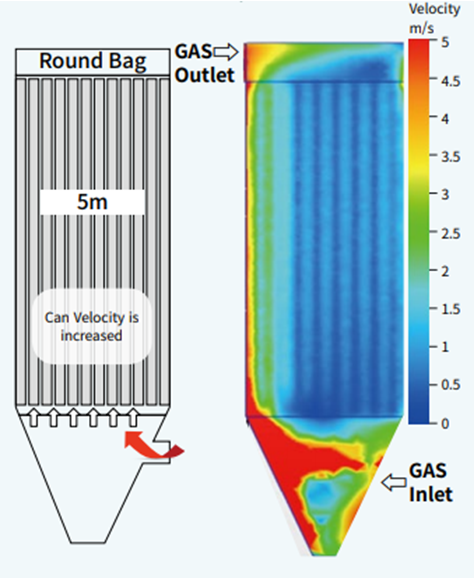

Gas flow simulation test (CFD) was done as follows.

(a) Round filter bag (before improvement)

- In general, the round bag of 4m ~ 6m is applied to the existing bag filter. Flue gas enters the bag filter at a speed of 15-20m/sec from the duct.

- After the high-speed gas rushes to the opposite wall, it cannot be spread evenly due to the interference of the bag, and most of gas rises rapidly along the wall.

- Accordingly, an excessive load is applied to the bag on the opposite side of the inlet duct,

- Premature failure due to friction and/or collision between bags by high speed gas

- Partial wear and shorter life of some bags due to rush of gas with dust

- Even after pulsing, dust is re-entrained due to the fast rising gas velocity, and performance is degraded.

(b) Improvement by replacing with EPiT pleated bag

- Replace the 4m round bags with 2m EPiT Pleated Bags to existing bag filter. Rather, the filtering area is increased and the ACR is improved. ½ of the existing bag house becomes empty space.

- Likewise, the high-velocity gas is evenly distributed as it goes up the empty space of bag house, its gas velocity is lowered. (Gas flow balance).

- And the lower-velocity gas will rise evenly between the bags,

- Abrasion and/or collision between bags are greatly reduced, and premature failure is also reduced.

- Coarse dust falls by its own weight, and dust re-entrainment is reduced by lower-speed gas with less buoyant.

- The even distribution of gas with reduced dust concentration extends bag life time and improves dust collection efficiency. Also, energy saving effect occurs with ΔP improved by lower re-entrainment.

EPiT supplies major parts for bag filter .

1. Pulse jet air system

-

- Pulse jet air system

2. Ash handling system

-

- Ash handling system